Robot Marking Systems – Industry 4.0

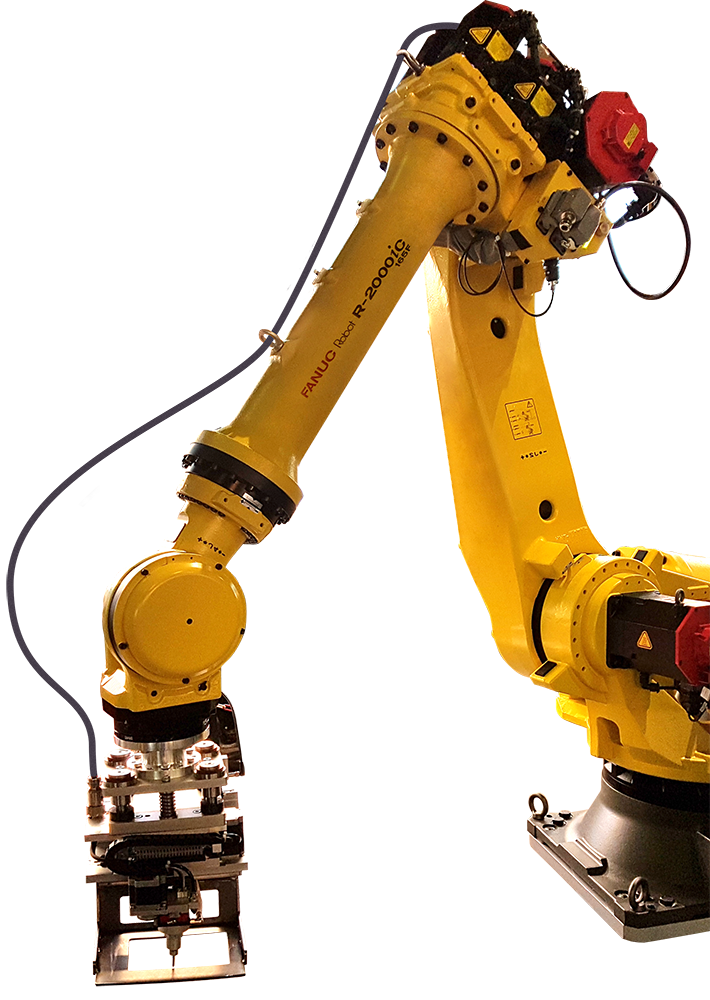

Robot marking systems are suitable for marking at high product temperatures and can achieve penetration depths of up to 1.2 mm in hot steel. The well-proven 6-axis robot marking systems are specially developed for the steel mill industry. The robot in combination with a STOMMEL+VOOS needle embossing machine is ideally suited for industrial requirements. Even on extremely uneven surfaces the marking or stamping of lettering, logos or codes (Data-Matrix) is no problem. Coarse sheets, rings, railway wheels, beams or pipes can be stamped or marked with a character code or a data matrix code.

The robust mechanics and the powerful impact needle of the needle stamping heads were developed for use in the iron and steel industry. An ingenious heat protection housing and efficient cooling systems enable the marking process to take place at extremely high temperatures.

The marking range is almost unlimited, since the 6-axis robot can control every conceivable spatial marking position and even markings at positions that are difficult to access are possible.

Product changes can be carried out easily by the operator without mechanical modifications of the marking system.