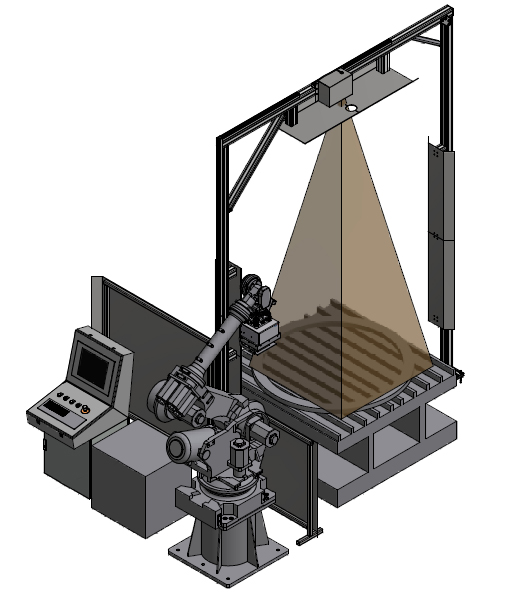

Robotic Pin Stamper

Labeling with our Pin Marking System is carried out by an oscillating hard metal tip, which can be moved in the X and Y directions using a coordinate unit with two stepper motors.

Any text, numbers and special characters, logos, etc. can be embossed within the labeling field. In continuous operation, the lettering consists of a dense sequence of individual overlapping dots that will form a closed line.

Due to the relatively large stroke of the needle tip, even slightly uneven surfaces can be easily marked. Limited jacket labeling (depending on the height of the digits and the work piece diameter) can also be realized.

Depending on the selected font size, the software allows labeling with up to 26 lines of text. The system is provided with a USB interface, which allows the connection to an external PC.

Our marking systems can be used for various applications. Integration into a robot system and a production line is just as possible as a hand-held version. The needle embossers, specially developed for the steelworks industry, in combination with tried and tested 6-axis robots, are suitable for marking at high product temperatures. The industrial requirement of a data matrix marking in combination with a readable code and a permanent “non-losable” marking are optimally covered by this stamping process. An unmistakable marking image is created even on extremely uneven surfaces. A sophisticated thermal protection housing and efficient cooling systems enable the marking process even in fiery environments. The marking range is almost unrestricted, as the 6-axis robot allows any conceivable spatial marking position to be controlled, and even marking in hard-to-reach positions is possible. Product changes can be easily carried out by the operator without mechanical modifications to the marking system.